Savonia Article: Industrial Collaboration Enhanced: Mobile and Arm Robots in 5G-Powered Partnership

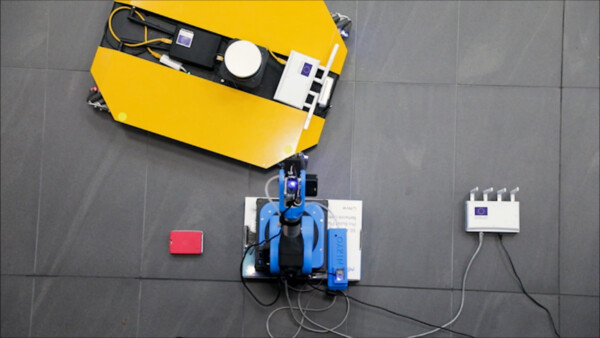

In the field of industrial automation, advanced technologies have become essential for improving efficiency and adaptability. This article explores a significant pilot project demonstrating the potential of 5G technology to transform industrial collaboration. The project illustrates the cooperative capabilities of two distinct robots, the Clearpath Dingo-O mobile robot, and the Niryo Ned/Ned2 arm robot, while highlighting the impact of 5G connectivity on their collaboration.

Our Robotic Duo

At the core of this pilot project lies a collaboration between two robots, each with specialized functions. Firstly, Dingo, a mobile robot, transports objects within an industrial environment. Dingo’s autonomy derives from its autonomous driving system and AI model, hosted on 5G edge server. Real-time communication between Dingo and the edge server occurs through the Savonia 5G network.

Niryo’s Role

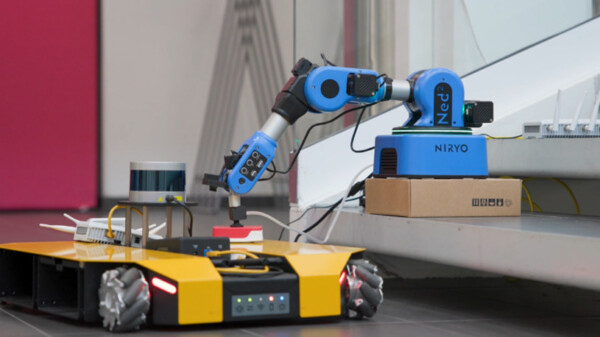

Complementing Dingo’s mobility, Niryo Ned/Ned2 an arm robot, interacts with objects. Niryo uses an object detection AI model based on YOLO technology. YOLO, short for You Only Look Once, is an efficient object detection algorithm that uses a single end-to-end neural network. It can identify and locate objects in real time with just a single pass over an image. This makes it a valuable tool for applications such as self-driving cars, surveillance systems and more. This pilot leverages the speed and accuracy of YOLO to improve object detection to achieve better results in our specific application. Thus, Our YOLO model enables Niryo to detect Dingo and control Dingo’s movement.

When Dingo approaches Niryo’s workspace, the Niryo’s YOLO AI model detects Dingo’s presence. Niryo then controls Dingo, parking it and placing objects on its platform.

Niryo’s involvement extends further, as it signals Dingo to move to the next robot in the workflow. The subsequent Niryo robot repeats this process, ensuring Dingo is parked correctly and handling tasks like identifying and placing a Raspberry Pi box.

The 5G Connectivity

Central to this collaboration is real-time communication using the Savonia 5G network. Dingo and Niryo robots rely on this high-speed, low-latency connection to communicate with the edge server, enabling swift decision-making, object detection and coordination without delay.

The 5G network empowers the robots to adapt to the dynamic industrial environment, facilitating rapid decision-making and task optimization. It serves as the infrastructure supporting the pilot, transforming a static industrial environment into a responsive one.

Conclusion

The success of the pilot depends on the Savonia 5G network serving as a foundation for collaboration. It facilitates quick communication and adaptation, underscoring its pivotal role in this partnership. Looking ahead, this mobile-arm robot collaboration pilot exemplifies how technology can drive innovation in the industrial landscape. The future holds potential for 5G-powered collaborations, with this project marking the start of a transformation in industrial automation.

Video: https://www.youtube.com/watch?v=_5PUG0G4fss

Project information:

5G:llä vauhtia digitalisaatioon (REACT-EU EAKR / Pohjois-Savon liitto, A77467)

Funders of the project:

Authors:

Mahdi Belila, Software Developer, mahdi.belila@savonia.fi

Premton Canamusa, Software Developer, premton.canamusa@savonia.fi

Osman Torunoglu, R&D Specialist, osman.torunoglu@savonia.fi

Timo Lassila, Test Engineer, timo.lassila@savonia.fi

Aki Happonen, Project Manager, aki.happonen@savonia.fi