Savonia Article: Long-term Research and Education Co-operation in Biotechnology

#SavoniaUAS

Adjunct Professor Elias Hakalehto (University of Eastern Finland, University of Helsinki and Finnoflag Oy) visited in Savonia’s Finnish Mechanical Engineering Degree Programme in the course Environmental Pollution Control and Prevention in Production Plants, which has been a tradition for several years.

Since the 1980s, Elias Hakalehto has lectured at Savonia or at the Kuopio Polytechnic, which preceded it, every decade in seminars and other events organized by Savonia. In addition to the above-mentioned course, he has given lectures for Environmental Engineering students, for example, related to energy and waste management technology courses, as well as in Bioeconomy Specialization education, which Savonia has been organizing together with Eastern Finland higher education institutions. In Bioeconomy Specialization education, a training day was organized for company representatives at Finnoflag Oy’s laboratory in INNOCUM Business Park, Siilinjärvi to teach microbial-based biorefining, i.e., the processing of organic waste and side streams into biomaterial compounds and energy products.

The collaboration between Elias Hakalehto and Savonia has continued for a long time also in research. For example, the first prototype versions of PMEU (Portable Microbe Enrichment Unit), innovated by him, have been developed together with Savonia. PMEU has been successfully tested e.g., in Savonia’s Environmental Technology’s Water Research Environment as part of the national POLARIS project (2009-2012) related to monitoring the purity of water distribution.

In his guest lecture, Elias Hakalehto told Mechanical Engineering students about the role and effects of microbes (bacteria, molds, fungi, yeasts, etc.) in nature, in our everyday life, in our bodies and health, and in industry. For example, one spoonful of yogurt contains the same amount of microbes as is the population on Earth, and whatever we ate as a child, the microbes that process this food live in our digestive tract throughout our lives.

In addition to microbiology, Elias Hakalehto also introduced the students to the key operating principles of nature, such as food production via photosynthesis, the most important nutrients and their circulation, food chains, metabolism, and the breakdown of organic matter. He also spoke about the corona very expertly and clearly, which deepened the students’ understanding of the cause of the COVID-19 pandemic.

Understanding the physiology of microbes is very necessary so that they can be widely used, for example, to produce valuable products from waste and side streams. This biorefining technology developed by Elias Hakalehto and Finnoflag Oy helps to replace and supplement fossil raw materials in the chemical industry with new environmentally friendly sources and processes.

Elias Hakalehto and Finnoflag Oy have piloted biorefining technology in several projects. One of them was the ABOWE project, in which Savonia, Finnoflag Oy and six partners from six countries in the Baltic Sea region cooperated. In the project financed by the EU’s Baltic Sea Region program, the Ministry of Employment and the Economy and the Regional Council of Pohjois Savo, a new type of biorefinery pilot plant was designed and built. The pilot plant was tested in Kuopio at the Powerflute (Savon Sellu) fluting factory, as well as in Poland and Sweden. Savonia acted as Lead Partner in the project, and Finnoflag Oy, acting as the Key Technology Provider, brought microbiology and biotechnology know-how to the design, construction and testing of the pilot plant. In ABOWE participated over one hundred Finnish students, teachers, and research & development specialists of various fields from vocational school, university of applied sciences, and university levels as well as representatives from companies. Accordingly, there were also experts from Germany, Poland, Sweden, Lithuania and Estonia. In ABOWE, a seminar and exhibition event was organized at the Finnish Science Centre Heureka, and the concluding seminar and exhibition event at the Viikki campus of the University of Helsinki. The results of the ABOWE project have been published in numerous international publications.

The products of biorefining are e.g.

• energy gases (such as hydrogen and methane),

• biofuels (such as ethanol and butanol),

• “Platform Chemicals” (such as valeric acid and 2,3-butanediol), which can replace oil in the production of plastic and synthetic rubber, for example,

• nutrients and safe food additives (such as lactic acid and mannitol),

• organic fertilizers and soil conditioners, which can be used to restore agricultural lands that have been spoiled due to erosion or excessive chemicalization to food production,

• cosmetic health-safe products,

• pharmaceutical industry components and raw materials for so-called excipients (carriers for tablets, etc.),

• clean air, water, and soil.

Elias Hakalehto told about biorefining in practice also through other projects, such as the Hiedanranta project of the City of Tampere. This project, “Zero Waste from Zero Fiber”, 2018-19 was financed by the Centre for Economic Development, Transport and the Environment. As raw material was used so-called zero fiber dumped by the forest industry, which had been operating for a long time (1913-2008). The 10-meter-thick sediment layer contains at least 1.5 million cubic meters of cellulose-containing fiber, which has accumulated in the environment as industrial side-streams during this time. Numerous Finnish and Swedish universities and companies have been involved in the Hiedanranta test projects. From the zero fiber, Finnoflag Oy was able to produce lactate with record productivity using microbes and their enzymes as well as mannitol, both of which have a significant value and a central position in, for example, the world’s food, pharmaceutical and chemical industries. The global market for these non-toxic, food-grade chemicals grows by approximately 10% annually. As was proven in the industrial piloting in Tampere Hiedanranta over a period of five years, it would be possible to reach again and again world-record yield and productivity in new generation biorefineries. At the same time, it would be possible to significantly produce, for example, bio-hydrogen and organic fertilizers to supplement the current deficit in energy and food production. There are thousands of similar sites, where non-degradable industrial material is at the bottom of waterways, around the world. In addition, for example, zero fiber is produced in operating factories all the time, and it is a valuable source of raw materials.

Industry does not need to pollute; it could adapt to the cycles of nature. By connecting in a series various processing and production processes of raw materials and side streams, the goal of Zero Waste can be achieved. Elias Hakalehto also talked about measuring production processes and brought up chemical and occupational safety aspects, which are very important for mechanical engineers.

Elias Hakalehto also told about other future visions, such as the hydrogen economy and growing food in big cities (City Food). On the other hand, in the greenhouse experiments conducted under his leadership at the Viikki campus of University of Helsinki, has been shown how it is possible to use microbes to enhance the binding of nutrients (nitrogen, phosphorus) to plants and improve growth. He has lectured on the possibilities of microbiological biotechnology and biorefining technology on six continents and has written numerous books and book chapters for the world’s leading scientific publishers.

Production processes based on microbes and their enzymes, as well as the hardware needed for these, must be designed in seamless cooperation, so that the hardware supports biorefining in an optimal way. Microbes work very quickly in their metabolism, when only the conditions are favourable for them. Elias Hakalehto emphasized the importance of know-how in mechanical engineering, for example when designing and manufacturing bioreactors and other bio- and waste processing equipment.

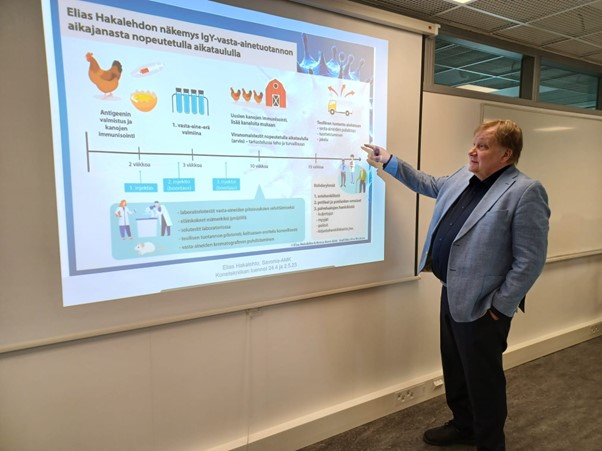

In medical biotechnology, more production capacity is also needed to meet the challenges of the time. These projects are particularly important for public health now and in the future.

The lecture was very interesting with versatile and illustrative examples, and the students certainly got inspiration and thoughts from it far into the future, thinking about sustainable development and taking it into account in their own work careers.

Further information about the EU’s Baltic Sea Region Programme project ABOWE (2012-2014): www.abowe.eu

Author:

Ari Jääskeläinen

Senior Lecturer in Industrial Management, M.Sc. (Tech.), B.Soc.Sc.

Savonia University of Applied Sciences