Savonia Article Pro: Leveraging IoT Solutions for Real-Time Data Acquisition

Savonia Article Pro is a collection of multidisciplinary Savonia expertise on various topics.

This work is licensed under CC BY-SA 4.0

Introduction

Time series data is an essential component in various fields including finance, economics, energy, environment and many more. Large collections of diverse data acquired over long periods of time can be used to create valuable information, which in turn can be converted to usable knowledge to form a basis for decision making. In recent times, artificial intelligence (AI) has become a viable means to extract such knowledge from seemingly meaningless numbers and other symbols, and it is a well-researched topic across industries. But where do those numbers and symbols come from?

Enter IoT

The Internet of Things, or IoT for short, has a history of being one of those arbitrary buzzwords no one agrees on the exact meaning of. In recent times, this still stands accurate. By definition, an IoT “thing” would mean any one thing that is connected to the Internet, which, in a broader sense, would apply to all modern computers, smartphones and other such devices used by humans for everyday tasks. A more specific acronym commonly used for IoT in industrial contexts is IIoT, or Industrial IoT. This could translate to any IoT device that is an Internet-connected “thing”, but which humans don’t directly interact with, and this would indeed be the type of IoT discussed hereafter.

At its core, a simple IoT data collection solution consists of one or more sensors connected to some kind of a data ingestion and storage service. In practice, IoT sensors are most often power-constrained, integrated devices connected to the Internet either directly or via an intermediary system called an “edge” device. The data ingestion service in turn usually consists of an Internet-facing network server with APIs for receiving measurement data, and a database system in which the received data is kept for further processing. These components are set up so that they operate automatically, without human intervention.

The ÄLLITÄ Project

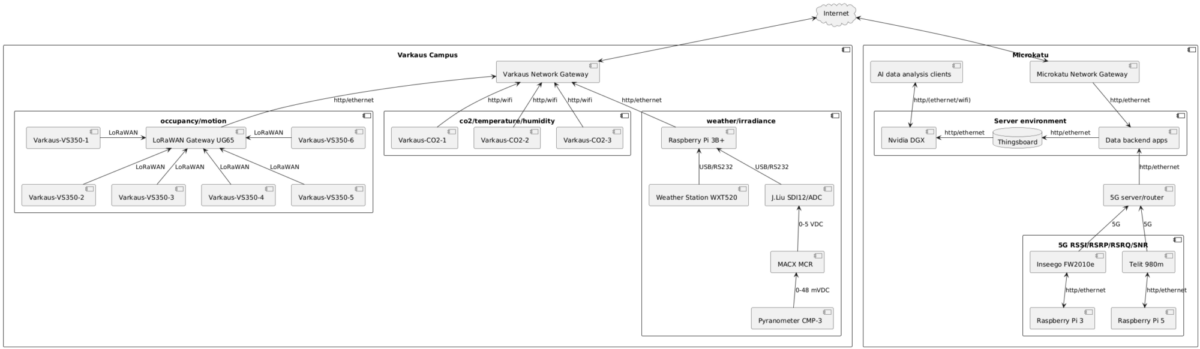

During the course of the ÄLLITÄ project, numerous IoT devices have been installed on the Savonia campuses in Varkaus and Kuopio. As the primary objective of the project is to develop new AI solutions for optimizing energy consumption in public buildings, these devices are used to monitor parameters such as the occupancy level of different parts of the building, as well as local weather conditions. The overall configuration of the IoT components devised for the purposes of this project is illustrated in the diagram below (Figure 1).

As seen in the figure, the data ingestion services reside on-premises at the Microkatu campus in Kuopio. Data transfer between the two sites is done over a secure communications tunnel, which is part of the Savonia IT infrastructure and, as such, out of the scope of this project.

On the Varkaus campus, occupancy levels are monitored by measuring the changes in CO2 concentration of the air in selected rooms. For this purpose, a custom IoT system consisting of a Sensirion SCD30 sensor module and an ESP32S3-based microcontroller was developed. Three of these systems were built, programmed and deployed to different rooms inside the campus building. Data from the devices is periodically sent to the HTTP API of the on-premises data platform (Thingsboard) utilizing the built-in WiFi capabilities of ESP32S3.

Additionally, six Milesight VS350 2-way PIR motion sensors were installed at selected observation points on the campus to count the people entering and exiting the monitored spaces in a given timeframe. These sensors use LoRaWAN radio technology to communicate with a Milesight UG65 network gateway, which was deployed at a central location on the site and connected via Ethernet to the campus’s internal network. The gateway was configured to relay any data it receives from the motion sensors to the HTTP API of the data platform.

Lastly, weather conditions at the Varkaus campus are observed by utilizing a Vaisala WXT520 multi-parameter weather station installed on the roof of the campus building. This particular weather station unit lacks the capability to monitor solar irradiance, thus, a custom IoT system consisting of a Kipp&Zonen CMP3 pyranometer, a Phoenix Contact MACX-MCR signal amplifier and a LiuDr SDI12/ADC board was developed for this purpose. Both the weather station and the pyranometer set-up are ultimately connected to a Raspberry Pi 3B+ single-board computer, which periodically reads values from these devices and sends the results to the HTTP API of the data platform.

On the Microkatu campus, two more Raspberry Pi devices with custom software were connected to two different 5G routers/CPEs of the campus’s 5G testing infrastructure for obtaining 5G signal quality parameters. This data is periodically fetched from the 5G devices’ management interfaces and sent to the HTTP API endpoint of the on-premises database system.

Data analysis, AI model development and other activities that require access to the collected timeseries data are performed on an NVIDIA DGX computing platform, which, similarly to the database system, is located inside the on-premises server environment. Much like the process of storing new data into the database, the fetching of previously stored data from the database can be performed via simple REST API calls from the development environment. As the data collecting happens in real-time, new data can be used instantly for inference in various AI-powered applications, while the long-term, historical data accumulated over time can be used in developing the underlying AI models for said applications.

Conclusion

Low-level data management in IoT projects can become overwhelming as the number and variety of devices in the system increases. Adding a new sensor into an IoT system could in the best case be a matter of fire-and-forget, but more often than not some modification, or at least configuration of the device or its software, is necessary. Having a well-defined yet flexible data backend in place makes adding new sensors into an IoT system easier, but it is always crucial to carefully plan the procurement and integration process of new devices to avoid problems later on.

Authors:

Mika Leskinen, RDI Specialist, DigiCenter, Savonia University of Applied Sciences, mika.leskinen@savonia.fi

Shahbaz Baig, RDI Specialist, DigiCenter, Savonia University of Applied Sciences, shahbaz.baig@savonia.fi

Premton Canamusa, RDI Specialist, DigiCenter, Savonia University of Applied Sciences, premton.canamusa@savonia.fi

Aki Happonen, Digital Development Manager, DigiCenter, Savonia University of Applied Sciences, aki.happonen@savonia.fi

Laura Leppänen, RDI Specialist, Savonia University of Applied Sciences, laura.leppanen@savonia.fi