Savonia Article Pro: Performance-focused machine capacity simulation – part 1: Introduction

Savonia Article Pro is a collection of multidisciplinary Savonia expertise on various topics.

This work is licensed under CC BY-SA 4.0

In today’s manufacturing environment, suppliers confront increased pressure to deliver products fast while managing their limited resources, varying customer demands, and unpredictable production disturbances. It is essential to understand how daily operational decisions can influence throughput, delivery reliability, and machine utilization. However, analyzing these factors directly in the real production environment is often time-consuming and resource-intensive.

Simulation helps enterprises understand the impact of operational decisions on overall system performance in a risk-free computer-based environment. This allows them to measure how scheduling rules, machine setups, or customer priorities affect key outcomes, such as throughput, lead time, and delivery reliability. In this way, the simulation model allows companies to experiment with different capacity scenarios and anticipate the impact of decisions before implementing them in real operations.

The model is mainly designed for SME subcontractors, production planners, and manufacturing managers who need to analyze production efficiency, workload optimization, and enhanced collaboration with primary operators.

This operational model consists of three parts and was made as part of the Simulation models in industrial processes project, co-funded by the European Union. The first part gives a more general introduction of the case, the second part describes a simulation model which was made by Anylogic software, and the third part proposes example scenarios and use cases for the model and how companies would benefit of the model. The case was made in collaboration with three manufacturing companies in North Savo, and the results provide an example of a data-driven and visual simulation tool for capacity planning.

Purpose of the Operational Model

The operational simulation model illustrates how the production system behaves under realistic conditions. It replicates the flow of production jobs in a bottleneck workstation, capturing real manufacturing behaviour such as waiting times, setups, machining, equipment failures, and resource constraints. Reflecting these operational dynamics, it allows users to test different scheduling strategies, shift structures, and resource levels to understand their impact on performance. The model can provide insights into the following questions:

How do different scheduling rules influence throughput and waiting time?

Do overtime or additional shifts significantly increase output?

What is the impact of machine failures or maintenance on performance?

How much does actual production deviate from planned schedules?

Which factor contributes most to delays—waiting, setup, or failures?

What does the model need as input and provide as output?

The model requires basic job-related data that is usually available from an ERP system, such as setup times, machining times, planned start dates, and job priorities. In addition to this, users configure the system by selecting key operational settings. These include choices about shift length and overtime, the number of machines and operators available, the probability of machine failures, and the duration of maintenance activities, as well as parameters such as setup reduction initiatives and expected quality rates. Together, these inputs define how the system behaves and establish the conditions under which the simulation will run.

The model generates outputs that help users understand production performance. It reports the total throughput, meaning the number of jobs completed within the simulation period, and calculates Overall Equipment Effectiveness (OEE) along with its components (availability, performance, and quality). The model also breaks down how time is spent across different activities such as setup, machining, waiting, and handling failures. Additionally, it highlights the difference between total working hours and truly productive hours, enabling users to identify inefficiencies. All results are presented through intuitive visual dashboards, making it easy to interpret system behaviour and explore improvement opportunities.

The Three Core Layers of the Model

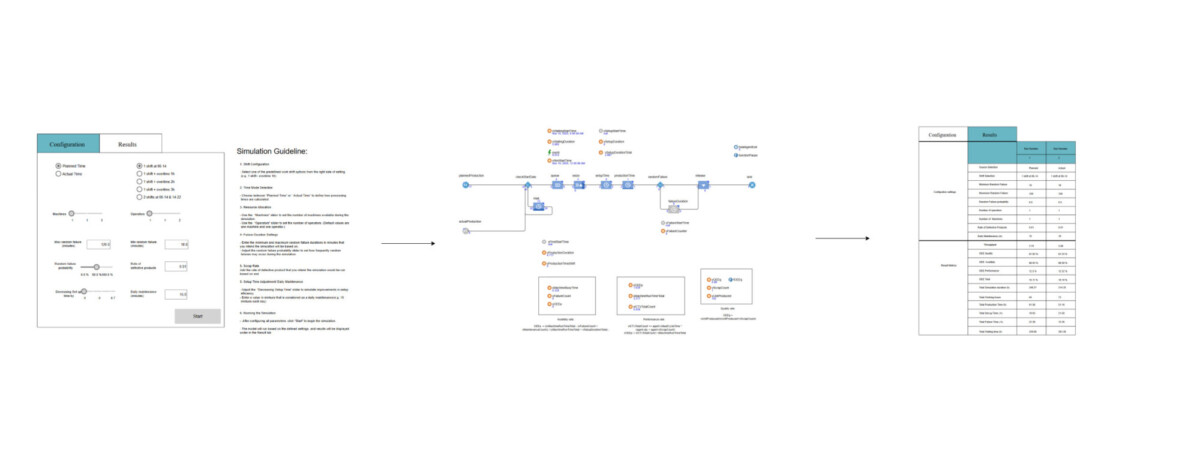

The simulation model is divided into three layers: a core layer, comprising the configuration layer, the simulation logic layer, and the results layer (Figure 1). The configuration layer allows users to define the operational conditions under which the system will run, including the choice between planned or actual data, shift length, resource availability, failure and maintenance settings, and quality or setup adjustments. This layer defines the boundaries for the experiment before any simulation activity begins.

Once all the parameters are set, the simulation moves to the second layer. This layer, which is the simulation logic, captures the actual behavior of the bottleneck workstation through the flow of jobs, queues, setups, machining operations, and possible equipment failures. Here, the model follows the operational rules defined earlier and replicates real production dynamics.

After all jobs are processed, the results layer compiles key performance indicators such as throughput, waiting time, OEE components, and time-based measures. Overall, these three layers present a transparent and systematic framework for evaluating production performance, and the following transition diagram illustrates how information flows from one layer to the next.

This article is made as part of Simulation models in industrial processes project. You can read more about project from here: https://sitepro.savonia.fi/ . The second and third parts of the article can be accessed here:

Performance-focused machine capacity simulation – part 2: Simulation description

Performance-focused machine capacity simulation – part 3: Example scenarios and benefits

Writers:

Sorayya Amirahmadi, Project Specialist, Savonia University of Applied Sciences

Ari Tanskanen, RDI Specialist, Savonia University of Applied Sciences