Savonia Article Pro: Real-time measurement of particle size and concentration in flue gases during biochar production – Dekati® ELPI®+

Savonia Article Pro is a collection of multidisciplinary Savonia expertise on various topics.

This work is licensed under CC BY-SA 4.0

The “Vesihiili” project investigates and demonstrates the production and use of biochar, including applications in water filtration and as a growing medium. Through these demonstrations, the project accumulates expertise in the use of biochar for filtration via field trials, while also supporting the launch of circular economy businesses based on biochar production. These actions help create conditions for new biochar-related economic activities, particularly in sparsely populated areas.

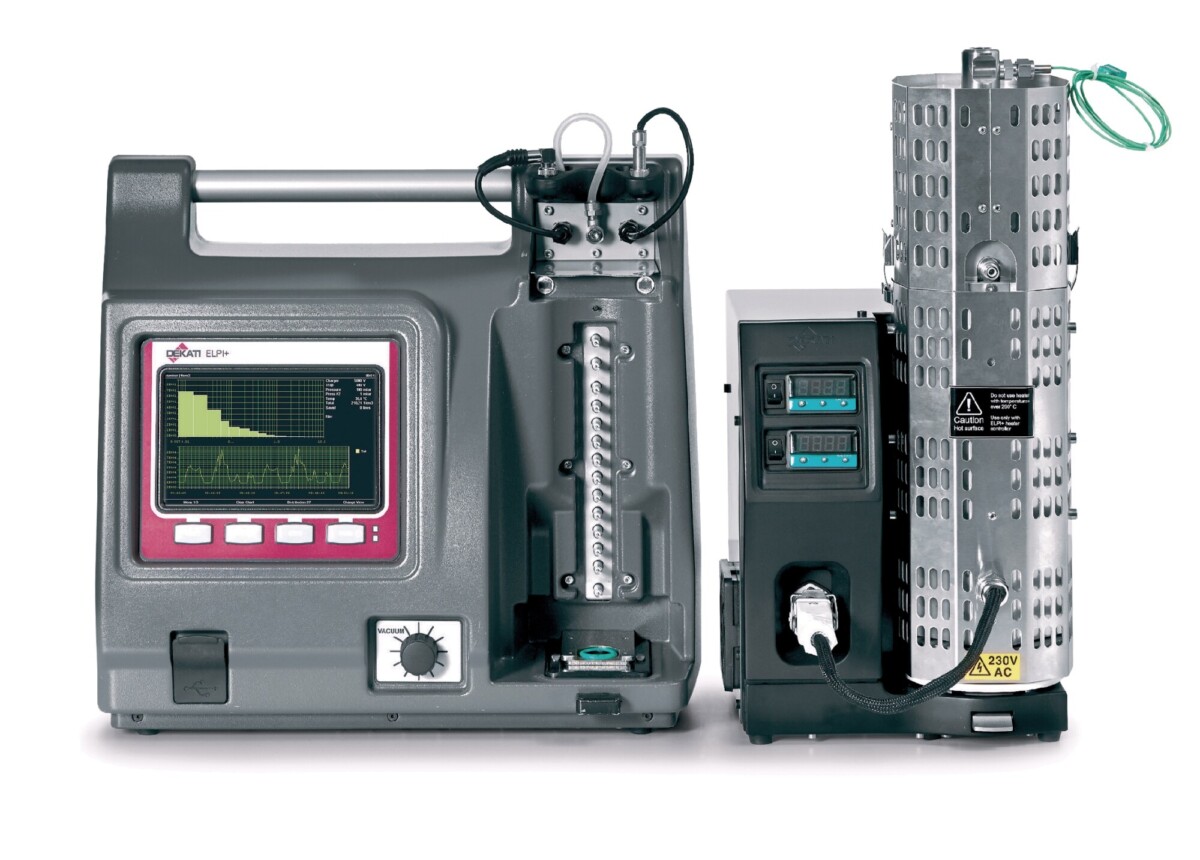

As part of the energy technology implementation, investments are being made alongside the development project, including the purchase of a Dekati® High Resolution ELPI®+ (Electrical Low Pressure Impactor, HR-ELPI®+), with the additional High-Temperature (HT) upgrade (Figure 1).

Operating principle of the device

With the ELPI®+ instrument, we are able to perform real-time measurement of particle size distribution and total concentration. The system covers a wide particle size range from 6 nm to 10 μm using a single measurement technique. Thanks to the HT-upgrade, we can measure gases between 10–180 °C without the need for dilution or sample conditioning. This allows us to provide accurate measurements even at low sample particle concentrations and without the risk of sample transformations in a dilution system. (Dekati 2024)

The measurement process begins by charging particles to a known level using a corona charger. These charged particles are then classified according to their aerodynamic particle size, which describes how a particle behaves in air and corresponds to the diameter of a sphere of unit density that has the same aerodynamic properties as the real particle. Size classification takes place in a 14-stage low-pressure cascade impactor. The first stage of the impactor acts as a pre-separator stage, removing particles larger than 10 μm from the sample. The last stage, covering 6 nm to 16 nm, is a back-up filter stage that collects particles too small to be deposited by impaction on the preceding stages. Each stage is electrically insulated and equipped with sensitive electrometers that measure the charge carried by the collected particles. The resulting current signal is directly proportional to particle number concentration and size. (Dekati 2024)

The system classifies particles into 14 size fractions, but it can be expanded to up to 500 fractions using the HR-ELPI®+ software, enabling highly detailed analysis (Dekati 2024). Our current applications do not require post-chemical or gravimetric analysis, which allows us to use sintered metal collection plates, enabling long-term maintenance free operation.

Measurement capabilities

As mentioned earlier, with our new HT-ELPI®+, we can measure high-temperature aerosols directly without dilution or additional sample conditioning. This gives us greater flexibility in how we support our projects and partners, as our services can now cover a wide range of applications, such as combustion process studies and emission measurements, development and optimization of emission cleaning devices, and general particle research. Thanks to the instrument’s portability, we can carry out these measurements directly at the required sites.

In the Vesihiili -project the ELPI®+ will be used to determine the particle size and concentration of aerosol-phase particles generated during biochar production. Biochar is produced through pyrolysis of biomass at high temperatures in an oxygen-free or low-oxygen environment. In slow pyrolysis, temperatures range from 300–700 °C, while in fast pyrolysis, they can reach 500–1000 °C (Afshar and Mofatteh 2024). This process also generates other by-bioproducts, including bio-oil and syngas. Subsequent combustion of these by-products also produces emissions, which depend on several factors such as the process conditions and feedstock. These emissions typically include, among others, carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide (SO2), nitrogen oxides (NOx) and methane (CH4), as well as aerosols.

The ELPI®+ allows us to track how different process parameters such as reactor temperature, residence time, and feedstock type influence aerosol emissions throughout the pyrolysis process. This information is important for both improving reactor performance and ensuring that biochar production systems meet environmental standards. Moreover, understanding particulate behavior helps in designing cleaner biochar technologies and evaluating the sustainability of different production pathways.

Our services already include accredited dust particle emission measurement using the gravimetric method. This method is the Standard Reference Method (SRM) described in the standard SFS-EN 13284-1:2017. A gas sample is taken isokinetically from the main stream for a known time and volume. Dust in the sample is captured on a pre-weighed filter, and any dust deposited upstream of the filter is also collected. After drying and re-weighing the filter and recovered deposits, the total increase in mass is attributed to the dust in the sampled gas, allowing the dust concentration to be calculated.

Comparing ELPI®+ with this gravimetric method highlights how number-based and mass-based approaches differ, especially for fine and ultrafine particles where mass is very small but number concentration is high. In addition, ELPI®+ results can be compared with the results of the plant’s continuous emissions monitoring systems and the gravimetric method as a quality assurance tool, increasing the reliability of the results.

Training

A two-day training session on the ELPI®+ instrument was conducted by Dekati experts at Riikinvoima Power Plant, a facility that generates clean energy from municipal waste using a 54 MW circulated fluidized bed boiler (Riikinvoima s.a.). During the training, the Vesihiili-project’s research team from Varkaus Campus gained insights into aerosol fundamentals, the construction and operating principles of ELPI®+ and HT-ELPI®+, and essential user maintenance procedures. Hands-on exercises included assembling the HT-ELPI®+ system and performing real-time measurements (Figure 2).

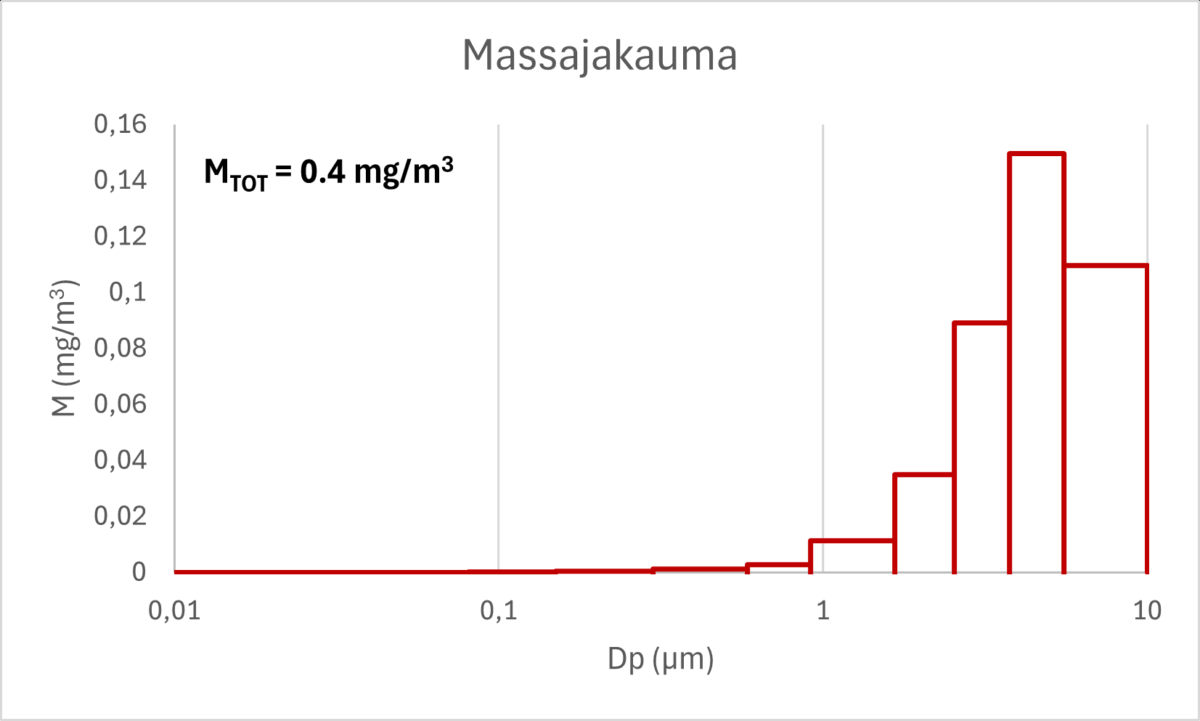

During the training, we also learned how to perform data-analysis using DAT software. The following graph (Figure 3) shows typical data that can be obtained from the instrument, illustrating the particle mass concentration distribution across the measured diameter ranges. The training session concluded with disassembly of the measurement setup and post-measurement maintenance, ensuring the team is fully prepared for particle analysis in future applications.

The Waterchar project is a project co-financed by the EU, financed from the Just Transition Fund (JTF), and the funding authority is the Regional Council of North Savo.

Authors:

Research Engineer Raquel Mier González, Savonia-amk

RDI specialist Maarit Janhunen, Savonia-amk

Research Engineer Janne Ylönen, Savonia-amk

Technical sales specialist Markus Nikka, Dekati Oy

Technical support engineer Paxton Juuti, Dekati Oy

References:

Dekati 2024. ELPI®+ User Manual Ver 1.7.

Afshar, M. & Mofatteh, S. 2024. Biochar for a sustainable future: Environmentally friendly production and diverse applications. https://doi.org/10.1016/j.rineng.2024.102433.

Riikinvoima s.a. Briefly in English. https://riikinvoima.fi/briefly-in-english/. Accessed 12.11.2025.