Savonia Article: Biorefinery combines mechanical engineering and the microbial system that sustains the life in Nature

This work is licensed under CC BY-SA 4.0

In April, Savonia’s first-year mechanical engineering students had as a guest lecturer in the Environmental Management of a Manufacturing Company course, Adjunct Professor and CEO Elias Hakalehto (University of Eastern Finland, University of Helsinki, Finnoflag Oy). This was the final lecture of the course, and at the same time a summary of many of the topics covered in the course. Microbes and their utilization in industry was a completely new topic for the listeners, and the guest lecture was a unique opportunity to hear a lot of interesting information, views, and also historical experiences on the subject.

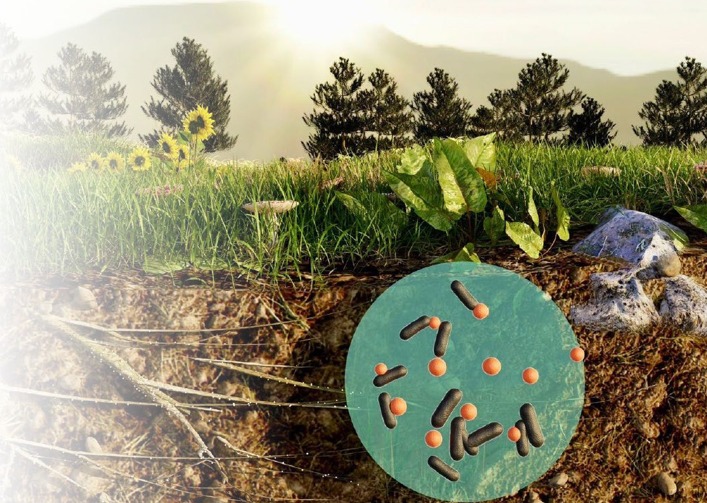

Elias explained in an illustrative way how microbes are everywhere: the air is full of them, as are, for example, the surfaces of tables and floors. Microbes are invisible to the eye – their size is about one micrometer – but the decomposition they perform is very essential for all life, and substances would not circulate, and we would not survive without them. Microbes should be studied and used for various applications. Nowadays, there is a lot of talk about so-called ecosystem services, and for example, the Deep Water Horizon oil rig accident in the Gulf of Mexico showed what a huge cleansing power the ocean’s own microbes have.

Elias studied microbiology and biotechnology at the University of Helsinki in the 1980s, and also took some courses at the Helsinki University of Technology (now Aalto University). He also committed to postgraduate studies in three Universities in London and Canterbury. In University College London, where vitamins were discovered in the 1930s and the production of antibiotics was developed, his main subject was Biochemical Engineering. There, Hakalehto got acquainted with biotechnology pilot plants and received guidance from absolute top experts in the field. His special lab project for the Institute for Biotechnological Studies was “Gene cloning in Streptomyces bacteria” (8mo) during which work novel cloning vector was developed in 1985 and used for the first cloning globally of an antibiotic gene (for clavulanic acid) in Escherichia coli. The bioprocessing of the latter is technically more straightforward and less challenging for the hardware.

Waste is not waste, but a raw material when used resource-wise

In his lecture, Elias told the students how utilizing various side streams generated in industry and other human activities is eco-efficient and economically profitable. He emphasized the importance of innovations for creating new resources and highlighted how nature can be used as a model for technical and economic production processes.

Elias mentioned examples from around the world, such as bioethanol production plants in China, the USA and Brazil, and biohydrogen production in, for example, China. These opportunities are also worth considering in Finland, where bioenergy production predominantly means the burning of wood-based energy sources. Here too, the many opportunities of biorefining could be utilized, such as producing biohydrogen using enzymes. This would provide new earning opportunities, for example, for the utilization of cellulose, the most common polymer in plants.

What is biorefining?

In biorefining, waste and biomass are used as raw materials, and microbes and their enzymes are utilized in the production process. The Earth’s vast biomass resources provide the conditions for this, and this would enable us to produce everything that is currently made from fossil natural resources. It is also possible to make harmless and pleasant products from side streams. There is currently a growing demand for biobased products worldwide.

Biorefining utilizes biocatalysis, which is created by microbes and their enzymes, and which allows the reactions in the production process to take place quickly, with low external energy input. The small size and abundant number of microbes mean that they have an enormous amount of reactive surface. Biocatalysis is enabled when the right conditions and nutrients are provided for the microbes. Biocatalysis is also needed everywhere in nature and, for example, in human cells. As an example, Elias told about bison, which are able to grow into muscle masses weighing a ton by eating almost nothing but dry hay. The secret is the microbial community in their rumen, which carries out biocatalysis. In addition, rumination enhances digestion, so bison get the most out of their food. As another example, Elias told about the feeding of cows on newspaper during wartime in Finland. The cows survived because their rumen had biocatalysis for this food source as well. Microbial cooperation also works in the human colon; probiotics and lactic acid bacteria enhance the activity of butyric acid bacteria, and the butyric acid they produce protects against cancer. According to Elias, it is essential to find microbial communities that function effectively in the given site. The microbial community breaks down raw materials and produces biogas, for example. There are a very large number of actors, and the process is very efficient. By feeding carbon dioxide into the biorefinery process, the microbial activity is further enhanced, and thanks to the metabolism of the microbes, carbon dioxide is bound to the products of the process. This offers the possibility of arranging a biorefinery plant as a carbon sink, where carbon dioxide captured from, for example, a power plant or industry can be fed as one of the production inputs.

What products can be produced with biorefinery?

Biorefining makes it possible to produce so-called platform chemicals, such as succinic acid, butanediol or valeric acid. These can be further processed into a wide variety of products, such as plastic, rubber, cosmetics and textiles.

For example, mannitol and lactate, or lactic acid, have been products of biorefining in Hiedanranta, Tampere, where there is an estimated 1.5 million cubic meters of zero fiber from former industrial times at the bottom of the lake. Zero fiber was once considered too short for the production of pulp and paper or cardboard, and therefore it has been dumped to the bottom of the lake. It is estimated that there are about 3,000 similar sites in the world. In studies conducted in Hiedanranta, bacteria that had been at the bottom of the lake for about 100 years worked together with microbes added by Finnoflag Oy, which are also natural, to produce mannitol and lactic acid, or lactate. The yield of lactic acid increased throughout the studies. Other products included ethanol, acetate and butyrate.

Finnoflag Oy has used cow stomach manure, which is microbial mass, as an aid in mannitol production experiments. This provided a biocatalyst for the record-high productivity of mannitol from fructose, which is an inexpensive raw material. Mannitol dissolves quickly and does not cause allergies, so it is, for example, a good carrier for drugs. It is considered a very important substance of the future for the pharmaceutical industry.

In the laboratory production of 2,3-butanediol, Finnoflag Oy achieved a productivity of 8 g / liter / hour in the early 2000s, while at the same time a world record of half that had been set in China. This platform chemical is also of great interest worldwide due to its many applications.

Biorefining requires mechanical engineering expertise

Biorefining requires various equipment and process technology to implement the production process. This requires expertise in, for example, mechanical engineering, electrical and automation engineering, information technology, as well as microbiology, biotechnology, chemistry and process technology.

In the biorefining process, gases produced by microbes in their metabolism, such as carbon dioxide, oxygen, hydrogen, ammonia and hydrogen sulfide, are measured and the necessary adjustments can be made based on the measurements. In its research and piloting, Finnoflag Oy has utilized the PMEU (Portable Microbe Enrichment Unit) it developed, which can accelerate and sensitize the detection of microbes. Product formation is also measured for process monitoring and adjustment.

Up until now, biorefining has been based mainly on human experience. In the future, a learning system utilizing artificial intelligence could be an opportunity to further improve the productivity of the process, i.e. the yield per unit of time. Biorefining could be bracketed to a suitable topic, such as mannitol production, and artificial intelligence could be used to optimize the process in question. Humans are still always needed for development, artificial intelligence cannot completely replace them but could act as an assistant providing process data to help human decision-making.

Biorefining should be taken to full industrial scale

According to Elias, biorefining should be organized as a step-by-step process so that the added value of production increases as high as possible. First, valuable liquid chemicals and energy gases, such as hydrogen, are produced from side streams and biomass. The remaining mass could then be used to produce biogas. The ABOWE project conducted test runs in Sweden with pilot installations for both biorefining and biogas production. The biogas experiments yielded a better methane yield from the mass after biorefining than from the anaerobic digestion of raw materials as such. The reason was that in biorefining, organic acids are formed from the raw material side streams and the mass remaining after the recovery of valuable substances allows the microbes in biogas production to produce methane more directly and efficiently.

Soil improvers are one possible end-product of biorefining, and the production of fertilizers is therefore vital for security of supply. On the other hand, UNESCO warns that 90% of the Earth’s surface land will be degraded away from agricultural use by 2050 if no improvements are made, causing a shortage of food and thus threatening biodiversity and human life. According to Elias, this could lead to migrations and wars.

Finnoflag Oy has studied the binding of nitrogen to soil and vegetation by bacteria and discovered an associative nitrogen binding mechanism, alongside the traditional symbiotic binding concept. In one of Finnoflag Oy’s experiments, the addition of a nitrogen-fixing microbial strain to a soil conditioner resulted in a 50% better yield in growing lettuce in two months compared to the traditional method.

Finnoflag Oy is the main partner in the BioResque project (Resource Recovery and Production by Industry Like Nature® Biorefinery, 12/2023-5/2025), funded by the EU’s CircinWater program. In this project, Finnoflag Oy is piloting the biorefinery of forest industry side streams, specifically into soil conditioners. It would be possible to address two issues at the same time: environmental problems caused by the forest industry and improving the world’s topsoil. Since 2015 Elias Hakalehto has served as the Vice President (Europe and Africa) of the International Society of Environmental Indicators. He has conducted about 150 R&D projects in agricultural, industrial, municipal and healthcare settings. There the urgency and necessity to implement ecosystem thinking into human technologies has become most evident for him.

According to Elias, biorefining is rapidly becoming more common. For example, the production of biogas and bioethanol already represent this, but as the examples in the lecture show, biorefining can be developed into larger and more diverse entities. Many pilot projects have already been carried out, now biorefining should be scaled up to a massive size in order to take full advantage of the many benefits of biorefining. Finnoflag Oy has produced solutions for biorefining, and the introduction of technologies must be regulated on a factory-by-factory basis. The forest industry has traditionally aimed at producing pulp, paper and cardboard, so resistance to change is prone to new opportunities. However, technical and scientific problems can be solved. As Hiedanranta case shows, biorefining would offer significant opportunities to utilize natural resources and at the same time clean up nature for human use.

Elias has edited and written several books based on his research and that of Finnoflag Oy and its partners. The latest book “Mixed Cultures in Industrial Bioprocesses”, published by the German Springer Verlag, the world’s second largest science publisher, was published in early May and the subject of the book is microbiological mixed cultures and their utilization in many applications, such as biorefining.

More information about ABOWE project:

https://www.savonia.fi/en/rdi-projects/abowe/about-abowe-project/

Author:

Ari Jääskeläinen

Senior Lecturer in Industrial Management, M.Sc. (Tech.), B.Soc.Sc.

Savonia University of Applied Sciences

Article has been previously published at Savonia-artikkeli 13.5.2025: Biojalostus yhdistää konetekniikan ja luonnon elämää ylläpitävän mikrobien järjestelmän